TECHNICAL CHARACTERISTICS

| Capacity |

5,2 m3/24hrs (up to 4 tons) |

| Dimensions, L*W*H |

3,3Х2,5х5,6 m |

| Power consumption |

1,1 kW |

| Nominal volume of the retort, m3 |

2,6 |

| Voltage, V |

380 |

| Nominal frequency, Hz |

50 |

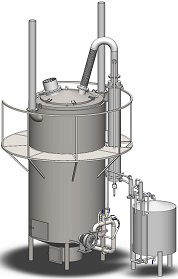

FORTAN plant is supplied with two retorts, made of heat-resistant stainless steel. The pyrolysis module is lined with high-temperature thermal insulation based on ceramic fiber and refractory concrete. During operation, the temperature of the module outer wall is safe for maintenance staff. The retort lid is manufactured with a lock with special design, which can provide a complete sealing of the space inside the retort and eliminate the possibility of smoke. FORTAN plants are provided with the necessary devices for control of process and control panel for adjusting the operation of the plant. Explosion-proof valve and gas emergency relief system ensure the safety of employees and equipment in case of a malfunction of the plant.

FORTAN plants are designed for mobile use: they have standard dimensions for transportation by any means of transport, a stand for transportation, flange connections in the whole structure, so the installation-dismantling process takes minimum time.

Specification of FORTAN pyrolysis plants:

| Pyrolysis module |

1 |

| Retort |

2 |

| Heat-exchanger |

1 |

| Tank |

1 |

| System of separators |

1 |

| Platform for service |

2 |

| Stand for transportation |

1 |

| Pipelines |

set |

| Passport |

1 |

| Control panel |

1 |

Please watch short video about FORTAN pyrolysis plants