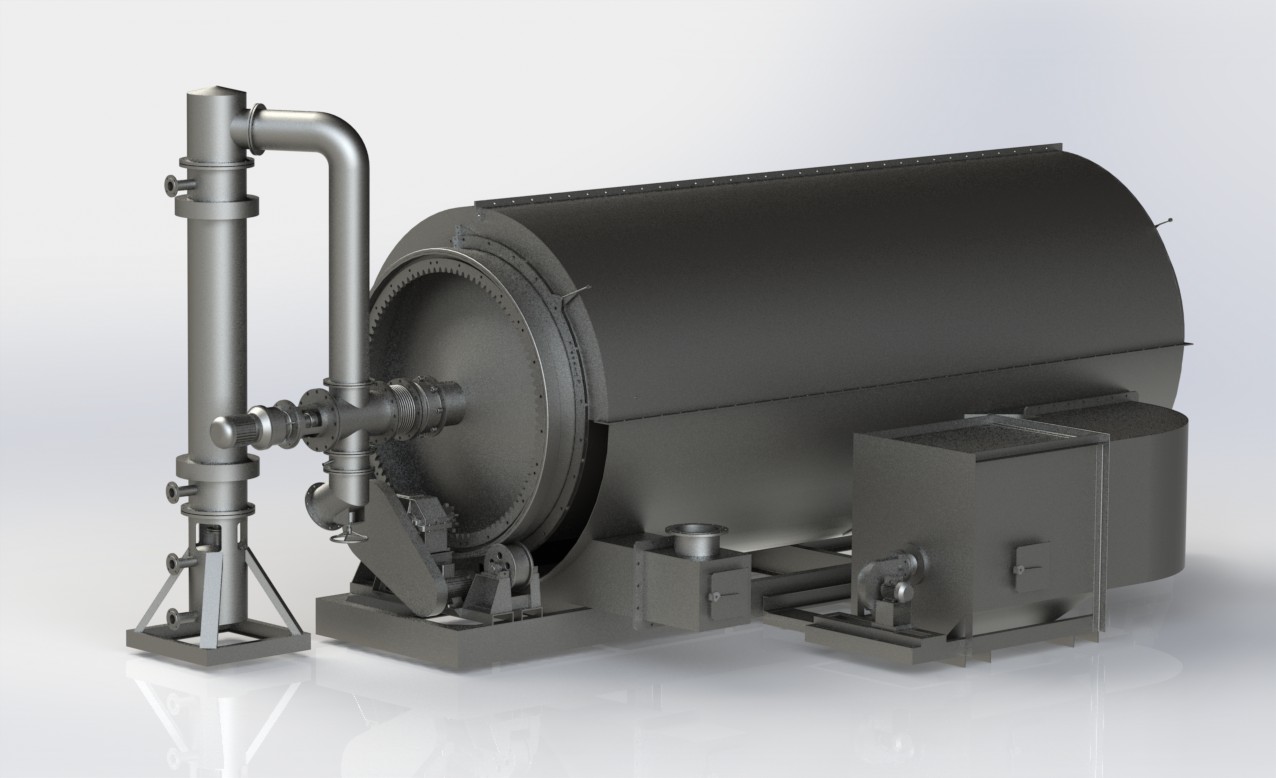

FORTAN-M plant has cylindrical horizontal rotating retort. Rotating retort allows processing of wastes with low thermal conductivity as, for instance, MSW. Retort is placed in the heating chamber. Heating chamber is heated with gases that goes out the furnace. Raw material is loaded into the retort through the opening at the end face with the front-end loader or with the belt conveyer. Then the door is airproof closed.

Pyrolysis oil is opaque combustible black liquid. Its characteristics depend on the combustible part of raw material. The residue after the process at FORTAN-M plant consists of carbon residue and mineral impurities. Carbon residue is a coarse-dispersion black powder. Mineral impurities are materials that cannot be processed: stones, glass, metal.

Carbon residue can be separated from mineral impurities with magnetic separator. Ash content of carbon residue depends on ash content of combustible part of raw material, mainly on content of small mineral impurities (dust, sand). Content of sulfur – 1…1,5% by mass. Residue after the process is unloaded with a screw conveyor of the plant.

Pyrolysis gas can be cooled for condensation of vapors of hydrocarbons to get liquid fuel – pyrolysis liquid fuel, or it can be directly burned.