TECHNICAL CHARACTERISTICS:

| Capacity |

72 m3/24hrs (up to 50 tons) |

| Nominal volume of the retort, m3 |

36 |

| Dimensions, L*W*H |

18,7*7,8*5,5 m |

| Diameter of the loading door |

1,2 m |

| Power consumption |

17 kW |

| Voltage, V |

380 |

| Nominal frequency, Hz |

50 |

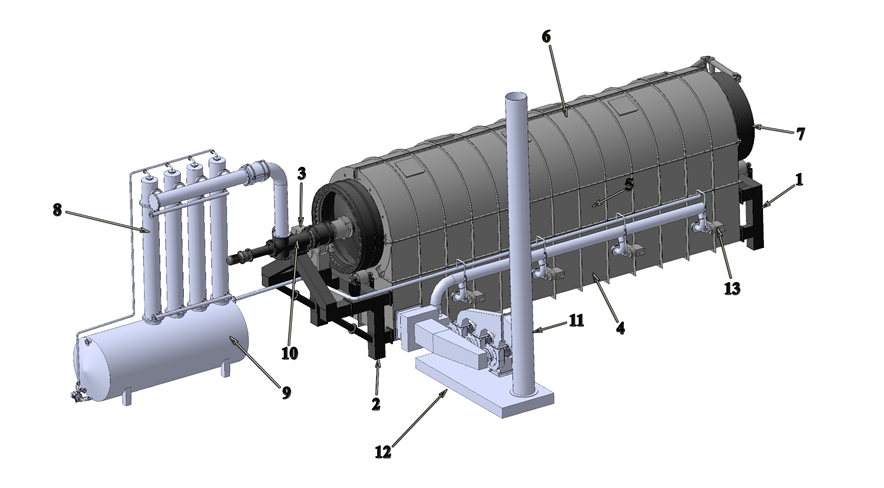

| 1. Front frame, 1 pc. |

| 2. Back frame, 1 pc. |

| 3. Engine, 1 pc. |

| 4. Low section of heating chamber, 2 pc. |

| 5. Middle section of heating chamber, 2 pc. |

| 6. Top section of heating chamber, 2 pc. |

| 7. Retort, 1 pc. |

| 8. Heat-exchanger, 1 pc. |

| 9. Tank with separators, 1 pc. |

| 10. Unloading system, 1 pc. |

| 11. Chimney, 2 pc. |

| 12. Smoke exhauster, 1 pc. |

| 13. Burner (liquid), 4 pc. |

| 14. Burner (gas), 4 pc. |

| 15. Pipelines, set |

| 16. Control box, 1 pc. |

The rotating retort PIROL is a metallic cylinder made of heat-resistant steel where steel bandages are welded from the ends. With bandages the retort is supported by four glides that are installed on hull frames of furnace at the loading and unloading ends of the furnace. Retort conical bottoms at the ends are equipped with round loading mouth (internal diameter is 1180 mm) and with the door at the loading end and with the unloading mouth at the unloading end. The loading door is pulled up to the loading mouth with 16 flap bolts. There is a special movable device (manipulator) to change the position of heavy door on the furnace body. The retort loading with raw materials is carried out through the door.

Pyrogas goes through unloading mouth to the condensing system; after the process finishes carbon black is unloaded automatically with unloading system.

A spiral is installed on inside wall of the retort: it helps to spread raw materials along the retort, to unload carbon residue after the process and provides better mixing of materials during the process.

Special spiral edges (movable) are installed on the internal bottom of retort unloading end. It provides the lifting of carbon residue to unloading mouth during unloading process.

The furnace body consists of heating chamber and two hull frames. The heating chamber is metallic cover that is lined interior with refractory and heat-resistant materials on the basis of ceramic fiber.

Four burner systems are installed under retort in heating chamber. The burners are for liquid fuels and pyrolysis gas.