Our company TT GROUP manufactures tire recycling plants - FORTAN and PIROL. Plants are designed for tyres recycling with thermal decomposition method - pyrolysis.

| FORTAN capacity |

5,2 m3/24 hrs (up to 4 tons) |

| PIROL capacity |

72 m3/24 hrs (up to 50 tons) |

Description of tyre recycling plants FORTAN and PIROL

Raw material (used tires) is loaded into a container made of heat-resistant material - retort. The retort is placed into the oven. Raw material is heated by heat transfer through the retort walls and thermally decomposed (this process is named pyrolysis) forming a mixture of vapor and gas and carbon residue.

The maximum operating temperature is 600 °C. Vapor and gas mixture exits the retort, goes to heat-exchanger, cooled and condensed. Liquid (pyrolysis oil) goes to storage tank. Gas (none-condensable) goes to gas-burner and partially or wholly is used to support pyrolysis process, or used to heat greenhouses, offices and so on. At the end of the pyrolysis process the retort with carbon residue is unloaded from the oven and the other retort with raw material is placed into it.

Pyrolysis module is lined with high-temperature thermal insulation based on ceramic fiber and refractory concrete. It provides low heat waste, low fuel consumption and fast temperature rising. Also temperature of the module outer wall is safe for maintenance staff. The retort lid is manufactured with a lock with special design, which provides a complete sealing of the space inside the retort and eliminates the possibility of smoke. Pyrolysis plants are provided with the necessary devices for control of process and control pannel for adjusting the operation of the plant. Explosion-proof valve and gas emergency relief system ensure the safety of staff and equipment in case of mulfunction of the plant.

FORTAN and PIROL plants are designed for mobile use: they have standard dimensions for transportation by any means of transport, a stand for transportation, flange connections in the whole structure, so the installation-dismantling process takes minimum time.

Output of products after tires pyrolysis:

| Liquid fuel (pyrolysis oil) |

35-45% by mass |

|

| Carbon black |

40% by mass |

|

| Steel cord |

8-10% by mass |

|

| Gas |

10-12% by mass |

|

*please request detailed videos and lab analysis of products and we will provide

How you can load tires into the pyrolysis plant:

Advantages of tires pyrolysis plants FORTAN and PIROL

1. The retort is made of stainless heat-resistant steel.

2. Furnace is multi-fuel: it is possible to use any kind of solid fuel and gas and to set a burner for any type of liquid fuel.

3. Lining is made from the fire-resistant fiber protected with a layer of the strong fire-resistant concrete reinforced with stainless steel, has high resistance against mechanical and chemical influences, provides temperature of an external surface of the plant not higher than 60C that is safe for operators to maintain the plant during the whole process.

4. Simplicity of a design. The increased reliability. A possibility of modification of a design to local conditions.

5. Means of explosion protection. Explosion-proof valve and gas emergency relief system ensure the safety of operators and equipment in case of a malfunction of the plant.

6. Easily repaired equipment.

7. The plant is easy-to-work and service, it is not required vocational education for operators, our company makes trainings for operators.

8. Mobility of the plant. Plants are designed for mobile use: have standard dimensions for transportation by any type of transport, flange connections in the whole structure so the installation-dismantling process takes minimum time, fixed concrete lining so dismantling of it is not required.

9. Low electricity consumption (10-14 kW*hour per each ton) and low fuel consumption (30-40 kg of fuel oil per one process).

10. Best price for same characteristics of equipment of other manufacturers.

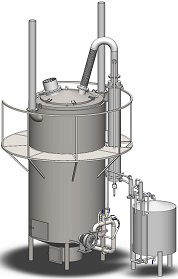

Technical characteristics of FORTAN plant 5,2 m3/24hrs (up to 4 tons)

| Capacity |

5,2 m3/24hrs (up to 4 tons) |

| Dimensions, L*W*H |

3,3Х2,5х5,6 m |

| Working temperature |

600 °C |

| Power consumption |

1,1 kW |

| Nominal volume of the retort, m3 |

2,6 |

| Voltage, V |

380 |

| Nominal frequency, Hz |

50 |

Specification of FORTAN pyrolysis plants:

| Pyrolysis module |

1 |

| Retort |

2 |

| Heat-exchanger |

1 |

| Tank |

1 |

| System of separators |

1 |

| Platform for service |

2 |

| Stand for transportation |

1 |

| Pipelines |

set |

| Passport |

1 |

| Control panel |

1 |

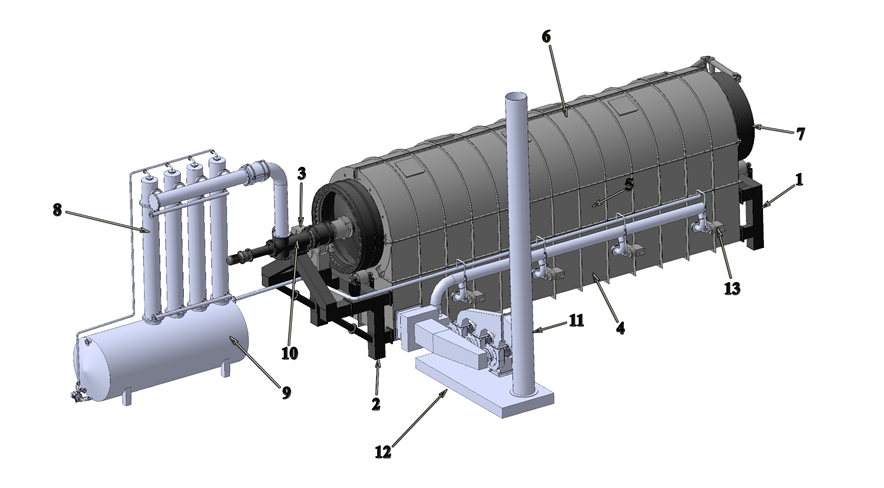

Technical characteristics of PIROL plant 72 m3/24hrs (up to 50 tons):

| Capacity |

72 m3/24hrs (up to 50 tons) |

| Nominal volume of the retort, m3 |

36 |

| Dimensions, L*W*H |

18,7*7,8*5,5 m |

| Diameter of the loading door |

1,2 m |

| Working temperature |

600 °C |

| Power consumption |

17 kW |

| Voltage, V |

380 |

| Nominal frequency, Hz |

50 |

| 1. Front frame, 1 pc. |

| 2. Back frame, 1 pc. |

| 3. Engine, 1 pc. |

| 4. Low section of heating chamber, 2 pc. |

| 5. Middle section of heating chamber, 2 pc. |

| 6. Top section of heating chamber, 2 pc. |

| 7. Retort, 1 pc. |

| 8. Heat-exchanger, 1 pc. |

| 9. Tank with separators, 1 pc. |

| 10. Unloading system, 1 pc. |

| 11. Chimney, 2 pc. |

| 12. Smoke exhauster, 1 pc. |

| 13. Burner (liquid), 4 pc. |

| 14. Burner (gas), 4 pc. |

| 15. Pipelines, set |

| 16. Control box, 1 pc. |

If you have any questions please contact us: