We manufacture EXON plants for production of biodiesel from any vegetable oil (including used ones) or animal fats.

EXON plants are designed for production of biodiesel from various vegetable oils (sunflower, rapeseed, soybean, palm, cotton, linseed, coconut, corn, mustard, peanut, castor, hemp, sesame, etc.), animal fats.

Biodiesel is a biological fuel that has consumption properties similar to diesel.

The operating principle of EXON plants is to carry out a chemical reaction of oils or fats of biological material with alcohol and alkali at high temperature, followed by filtration to obtain biodiesel. The main advantage of biodiesel is that it is produced from resources that are quickly recoverable.

Materials for production of biodiesel:

1. Raw material (sunflower, rape, soy-bean, palm, cotton, flax, corn, mustard, peanut, castor oil etc. and used vegetable oils), animal fats. Consumption raw material:biodiesel - 1:1.

2. Methanol / ethanol technical. Consumption - 120-140 kg per 1 ton of biodiesel.

3. Alkali - КОН or NaOH technical granulated high-grade. Consumption — 3-5 kg per 1 ton of biodiesel.

4. Sorbent - Amberlite BD10dry or analog. Consumption – 3-10 kg per 1 ton of biodiesel.

Products:

1. Biodiesel 1:1 with raw material.

2. Glycerin 120-140 kg.

| EXON-50 |

| Capacity - 1200 liters of biodiesel/day |

| Dimensions, length*width*height - 3,5x1,4х1,7 m |

| Power consumption - 14 kW |

|

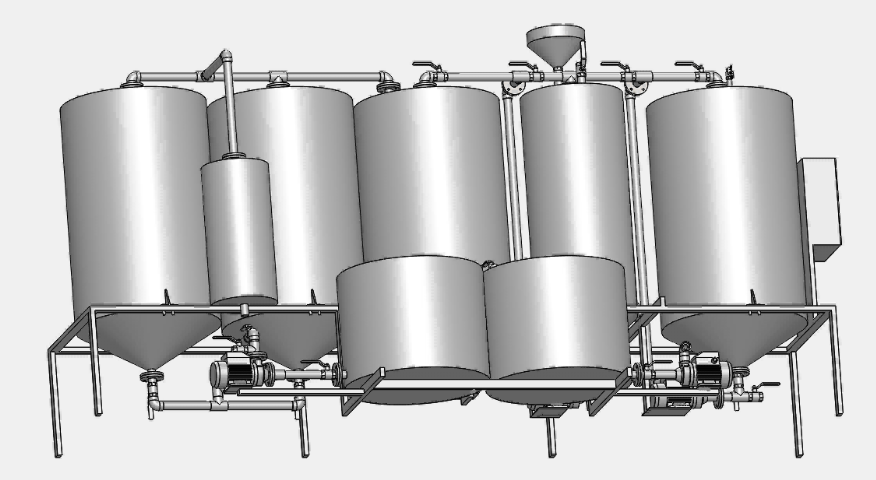

| EXON-250 |

| Capacity - 6000 liters of biodiesel/day |

| Dimensions, length*width*height - 7,2x3,2x3,3 m |

| Power consumption - 54 kW |

|

| EXON-500 |

| Capacity - 12000 liters of biodiesel/day |

| Dimensions, length*width*height - 9,1x4x4,1 m |

| Power consumption - 74 kW |

|

| EXON-1000 |

| Capacity - 24000 liters of biodiesel/day |

| Dimensions, length*width*height - 9,5x5x4,6 m |

| Power consumption - 57 kW |

|

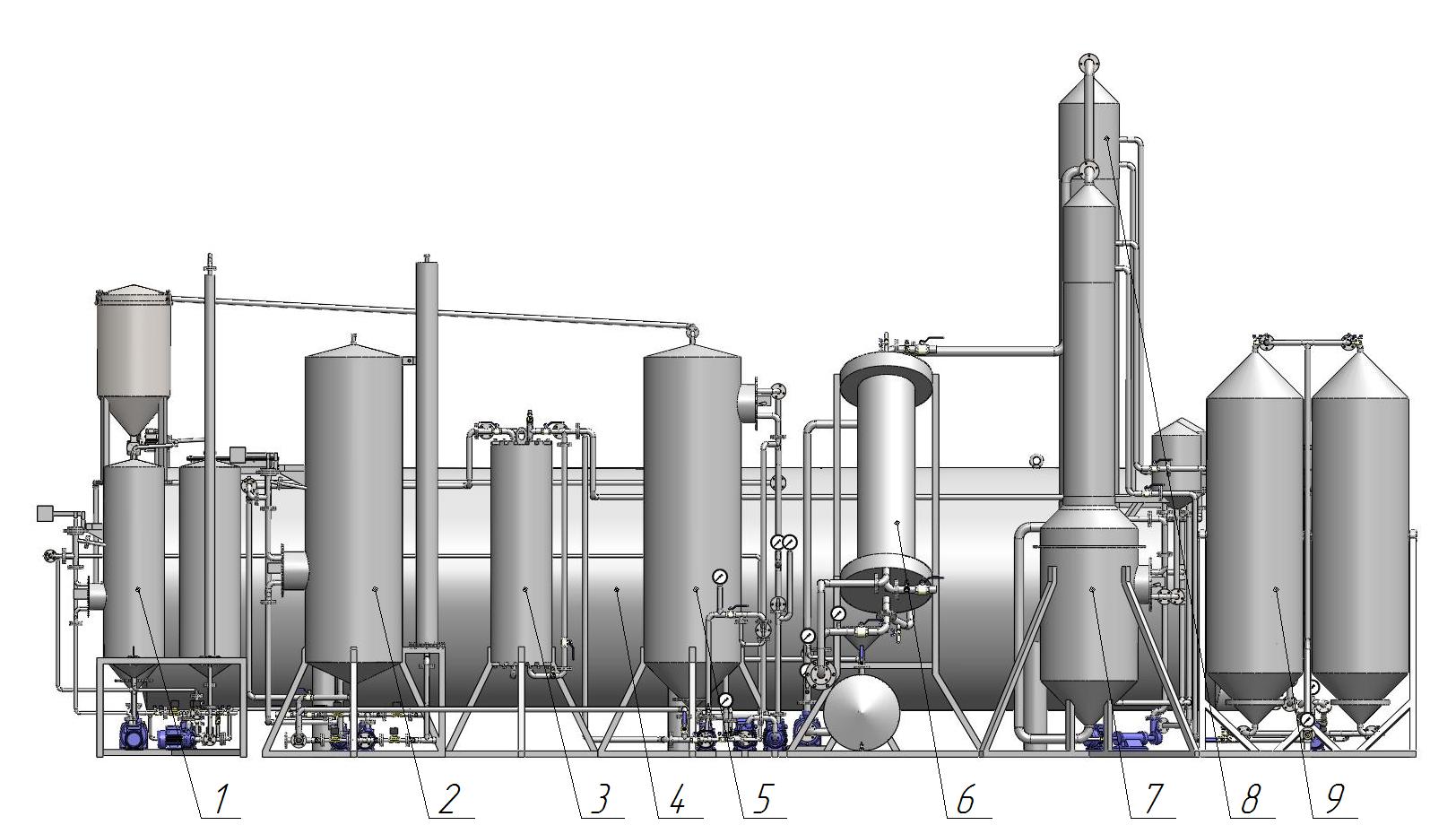

Specification of EXON biodiesel plants

1- Oil preparation module;

2- Module for synthesis of biodiesel;

3- Tank for biodiesel;

4- Tank for glycerin;

5- Module of biodiesel preparation;

6- Methanol recuperator;

7- Module of ilters;

8- Control panel;

9- Module of ilters;

10- Metal framework;

11- Platform;

12- Ladder;

Description of the biodiesel production process

Biodiesel is a methyl ester that is obtained by the chemical reaction of any vegetable oil and animal fat.

As you know, fat molecules consist of triglycerides or compounds of triatomic alcohol glycerol and three fatty acids. To obtain methyl ether, one unit of mass of methanol is added to 7 units of mass of vegetable oil (a ratio of 7:1 is obtained).

It is necessary to replace glycerol in glycerol esters with methanol (ethanol). This substitution is performed by a reaction between fat and alcohol to form methyl ether and precipitate glycerol, which is denser and insoluble in methyl ether. An acceptable reaction rate and degree of conversion can be obtained by raising the temperature, introducing excess alcohol, and using catalysts.

The chemical reaction produces the methyl ether that we need, as well as glycerine, which is widely used in the pharmaceutical and paint industry. The resulting ether has a good Flammability due to the high cetane index. If for mineral diesel fuel the cetane index is 42-45, then the cetane index of biodiesel (methyl ether) is at least 51. This allows it to be used in diesel engines without other substances that stimulate ignition. It is because of this property that the methyl ether obtained from vegetable oils and fats was called biodiesel.

Biodiesel can be used in conventional internal combustion engines, either separately or mixed with conventional diesel fuel, without changing the engine design.biodiesel production process.

We offer you a full range of services for our equipment:

| Warranty 2 years |

Supervising for equipment installation. |

| Start-up |

Teaching for staff |

| After-sales services |

Technical documentation |

| Technical support and consultation |

Transportation and shipment services |

| Custom clearance for export |

Required documents for import |

If you have any questions please contact us: